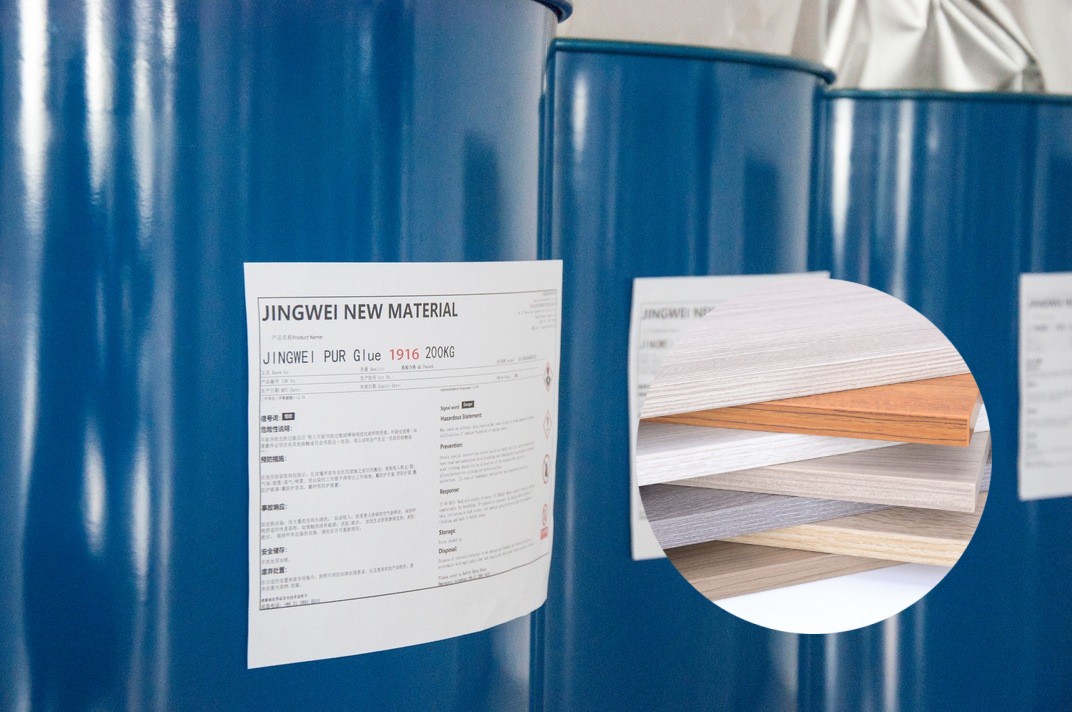

PUR Edge Banding Hot Melt

Description

Reviews

Introduction

1. Sealing PVC/ABS/CPL veneer edging strip, edging line speed 15m-25m/min, good operability, green, low comprehensive cost, easy to clean, fine glue line, less pollution, comparable to laser edging.

2. Suitable for a variety of materials, moisture-proof, mold-resistant and temperature-resistant. Long active period, applicable to open equipment; put an end to the traditional sealing quality after-sales problems.

3. High initial adhesion, 2mm sealing strip will not rebound, low operating temperature requirements, effective control of energy consumption, excellent workability.

Applicable Products

Product Categories

| Name | Color | Model |

Ambient Temperature |

Features and Applications |

|---|---|---|---|---|

| General | Natural | JW-1573 | 10-38℃ | Versatile for all seasons; high bonding strength, no cleaning, no glue line, good weather and solvent resistance. |

| Pure White | JW-1573 | 10-38℃ | Versatile for all seasons; high bonding strength, no cleaning, no glue line, good weather and solvent resistance. | |

| Summer | Natural | JW-1573H | Above 30℃ | High initial adhesion, resists crusting; ideal for narrow panel edge banding, prevents rebound in high temperatures. |

| Pure White | JW-1573H | Above 30℃ | High initial adhesion, resists crusting; ideal for narrow panel edge banding, prevents rebound in high temperatures. | |

| Winter | Natural | JW-1573C | 0-30℃ | High initial adhesion, cures at low temperatures, high final strength. |

| Pure White | JW-1573C | 0-30℃ | High initial adhesion, cures at low temperatures, high final strength. |

Product Performance

1. Strong initial adhesion, high final strength, and no rebound.

2. Temperature and moisture resistant, with good low-temperature resistance and excellent moisture-proof performance after curing.

3. Widely applicable for bonding various materials like PVC, PET, ABS, wood veneer, etc.

Precautions

1. Wear protective gloves and safety goggles when handling the product containing isocyanate. Avoid contact with water or moisture.

2. Use the glue within 48 hours after unsealing and heating. Replace if viscosity changes significantly.

3. Apply PUR glue evenly to prevent uneven glue lines. Cure in advance for better substrate adhesion. Shutdown machine to cool during breaks.

4. Adjust PUR edge banding to match natural humidity. Add a humidifier if air humidity is low.

5. Remove film from glue pot before adding glue. Seal the glue outlet with tin foil if not in use for a long time.

6. Use clean-free PUR edge sealing equipment. Wait for ten minutes before cutting after edge sealing.